Proshare Innovation Suzhou Co.,Ltd is the only high- tech company in China design and manufacturer the 3rd generation Thin Film Nanocomposite (TFN) reverse osmosis membrane and nano filtration membrane ,and become one of the few suppliers in the world produce specialty membrane .

The customer adopts ‘ammonia method’ to prepare iron phosphate process, iron / ferrous iron, phosphoric acid, hydrogen peroxide and ammonia reaction to generate iron phosphate, after the plate and frame press filtration, the wastewater enters the membrane treatment plant, after treatment, the concentrate into the evaporation, the water produced by low-pressure membranes and purified water membranes filtered for reuse.

The plant initially used special high-pressure and acid-resistant membranes from two other internationally renowned manufacturers, but the customer had higher requirements for energy consumption and operating expenses. As a result, the plant owner offered Proshare an opportunity to test with PSI MEMBRANE in small batches at the end of 2022 and start batch use in 2023, and after a year of stable operation, PSI MEMBRANE demonstrated superior rejection rate, flux and anti-fouling performance, reducing energy consumption and operating expenses. This positive result led to the replacement of more than 20000 high-pressure, medium- and low-pressure membranes and the appointment of Proshare PSI MEMBRANE as the group's formal supplier.

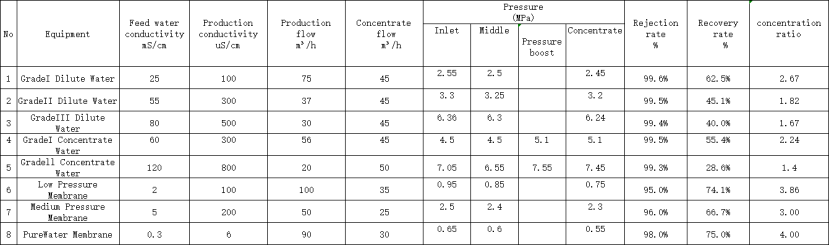

By the actual operation monitoring, we get the following data:

Proshare according to the existing process to put forward high-pressure special acid-resistant membrane further concentration and reduction of the programme, continue to help customers save operating costs, at present into the evaporation before the concentrate TDS = 135000mg / L, the plan is to be concentrated by the Proshare high-fold concentration of special acid-resistant membrane concentration into the evaporator after an average of TDS = 250,000mg / L

Base | Before Reduction | After Reduction | Reduction Rate |

A | 5100 | 2856 | 44% |

B | 4000 | 2240 | 44% |

C | 6000 | 3360 | 44% |

Based on the energy cost of evaporating one tonne of water, RMB 70, for 300 days/year, the total cost saving as follows:

Base | Before Reduction (m³/day) | After Reduction (m³/day) | Energy Saving | Energy Saving |

A | 5100 | 2244 | 15.708 | 4712.4 |

B | 4000 | 1760 | 12.32 | 3696 |

C | 6000 | 2640 | 18.48 | 5544 |

The combined annual cost savings for the customer were at least RMB 140 million, with the added benefit of generating additional economic value. The plant owner commented: “In the face of increasing water scarcity and rising economic costs, the adoption of sustainable water solutions is essential to minimise the environmental impact of manufacturing operations.”

We are delighted that our customers have responded positively to our PSI MEMBRANE series of high end reverse osmosis membrane and nanofiltration membrane along with expert commercial and technical support. The performance and results are a testament to the unique benefits and value that Proshare PSI MEMBRANE Solutions' technology and services bring to the industry.